- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

GST1050 Automatic screen printing spot UV & cold foil stamping line

GST-1050 Full Automatic Stop Cylinder Screen Press adopts the classical stop cylinder technology with the advantages such as: paper located exactly and steadily, high precision, high speed, low noise, high degree automatization and so on, it is suitable for printing on ceramic and glass applique, electron industry (film switch, flexible circuitry, meter panel, mobile telephone), advertisement, packing and printing, brand, textile transfer, special technics etc.

Main features:

1. Driven by a special brake motor for frequency conversion, the whole machine is centrally controlled and operated by Mitsubishi PLC programmable controller, 7-inch color touch screen operation interface, displaying all functional data, printing operation is simpler and more convenient;

2. Automatic optical fiber positioning detection throughout the process, line failure, paperless, jammed scraper automatically rise and stop or not, reduce the waste of printing paper;

3. Set up a perfect alarm bell alarm system to prompt the operator to carry out targeted troubleshooting, so that maintenance is easy and fast;

4. The whole set of electrical components are imported products from Schneider and Yaskawa, which greatly improves the stability of the electrical system and reduces the frequency and difficulty of maintenance and overhaul;

5. The cast iron frame and some components precision processed by the CNC "machining center" ensure the accuracy of key parts and ensure the stable and long-term rapid operation of the machine;

6. The printing cylinder is made of stainless steel 316L material, which is precise and durable; The flexible range of the paper tooth is designed to be flexible, which is convenient to adjust at any time when printing on different thicknesses and thin papers;

7. The paper output table that can be flipped 90 degrees, double conveying adjustable speed belt, practical size paper, convenient for screen cleaning, loading and unloading; Screen plate fine-tuning device, which can be adjusted in all directions up and down, front and back, left and right;

8. Good gray cast iron (HT250), wall plate and base cast by aluminum mold, after aging treatment, and then processed by imported large-scale three-dimensional machining center, high precision level requirements, smaller processing error, the operation of the whole machine is more stable and reliable.

9. Centralized lubrication control system: automatic lubrication of main transmission components, effectively prolonging the use accuracy and machine life;

10. The appearance is made of environmentally friendly primer, which is carefully polished and painted, and finally the outer surface cover varnish;

11. All pneumatic components adopt Taiwan Airtac brand, and the air pump adopts Becker vacuum pump;

12. Printing knife and feeder platform are precisely controlled by separate brakes, and the pressure is uniform;

13. The machine automatically detects whether there is paper or not, and automatically increases and lowers the speed;

14. One-button pneumatic switching device for pulling&pushing side lay

15. Mesh frame drawer design, can be pulled out as a whole, which is convenient for cleaning and loading and unloading of screen plates, and convenient for the calibration and adjustment of screen plates and prints.

Remark:

Equipped with independent single sheet paper reduction mechanism, feeding is more stable and reliable

Front gauge, pull gauge Japanese Keyence fiber inspection;

The paper conveying table photoelectric detection of whether there is material, deceleration and shutdown;

The latest double sheet detector

Details:

1. Feeder

The original rear pick-up feeder technology taken from the offset Press, ensures stable and smooth feeding of various types of substrate. Dependant on the substrate, overlapped or single sheet feed can be selected easily. Four suck and four delivery feeding system.

2. Delivery board

Imported stain steel delivery board, less static and friction. Rubber and the nylon wheel are suitable for the thin and thick paper adjustment

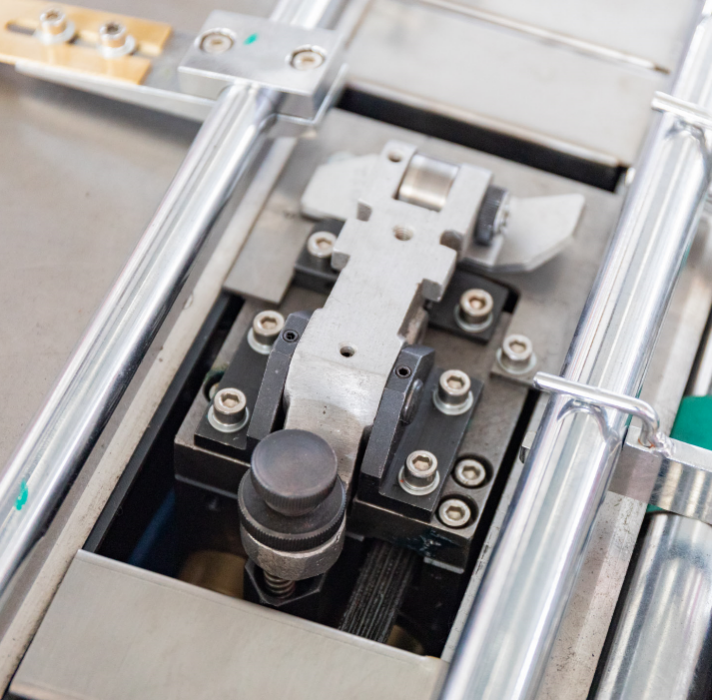

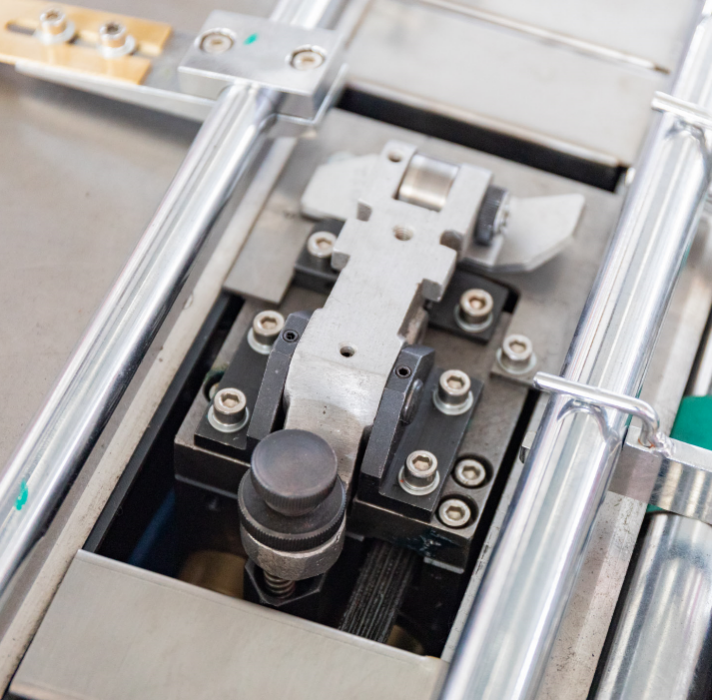

3. New designed pull and push lay

Controlled by the pneumatic switch, easy to switch the thin paper and thick paper, specially suitable for E-corrugated board printing

4. Paper output table

Double vacuum conveyor belt, controlled by the independent frequency. Suitable for different sheet size, avoid the damage to sheets and prevent the paper stuck,

The paper output table that can be flipped 90 degrees, convenient for screen cleaning, loading and unloading

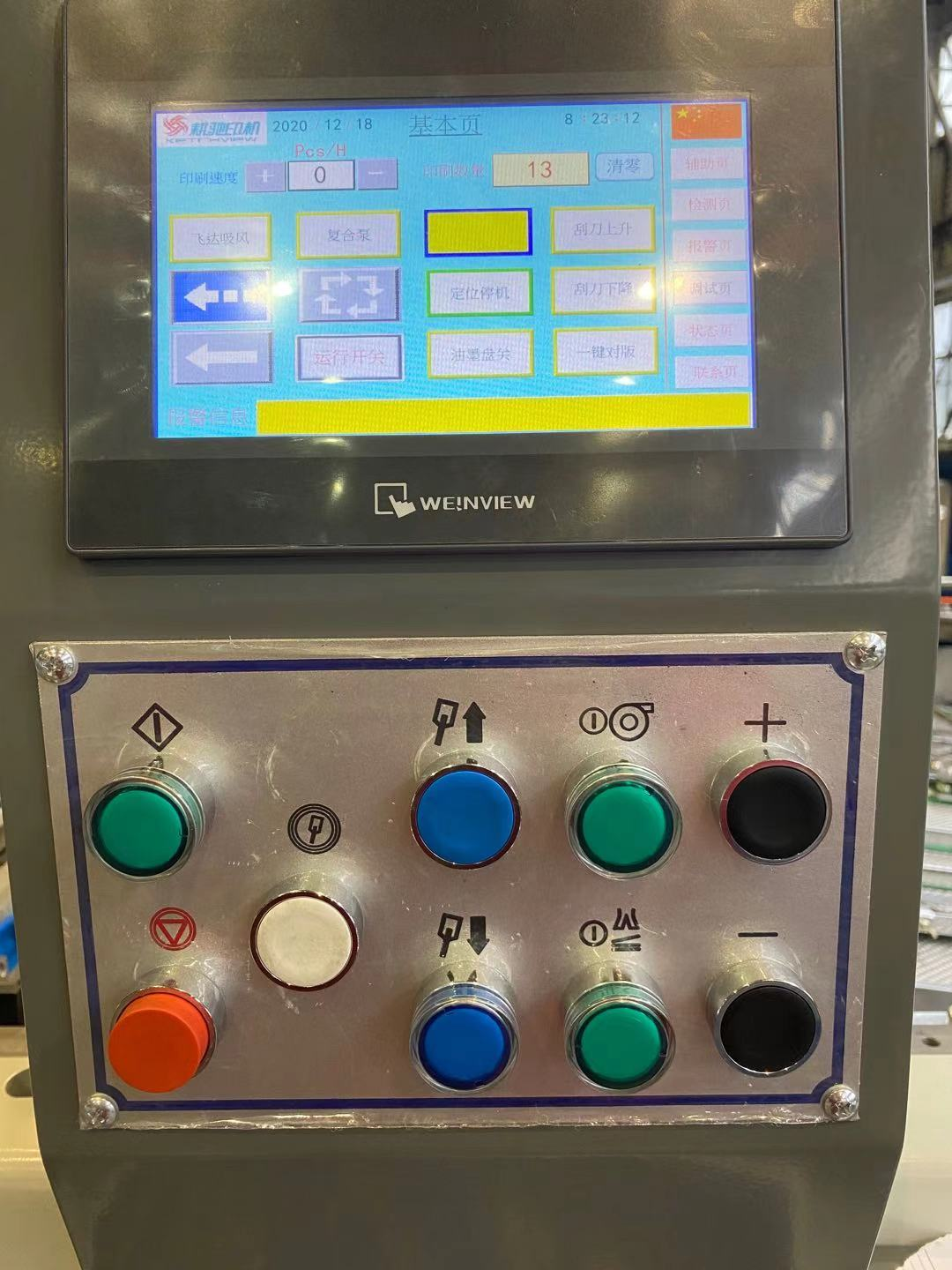

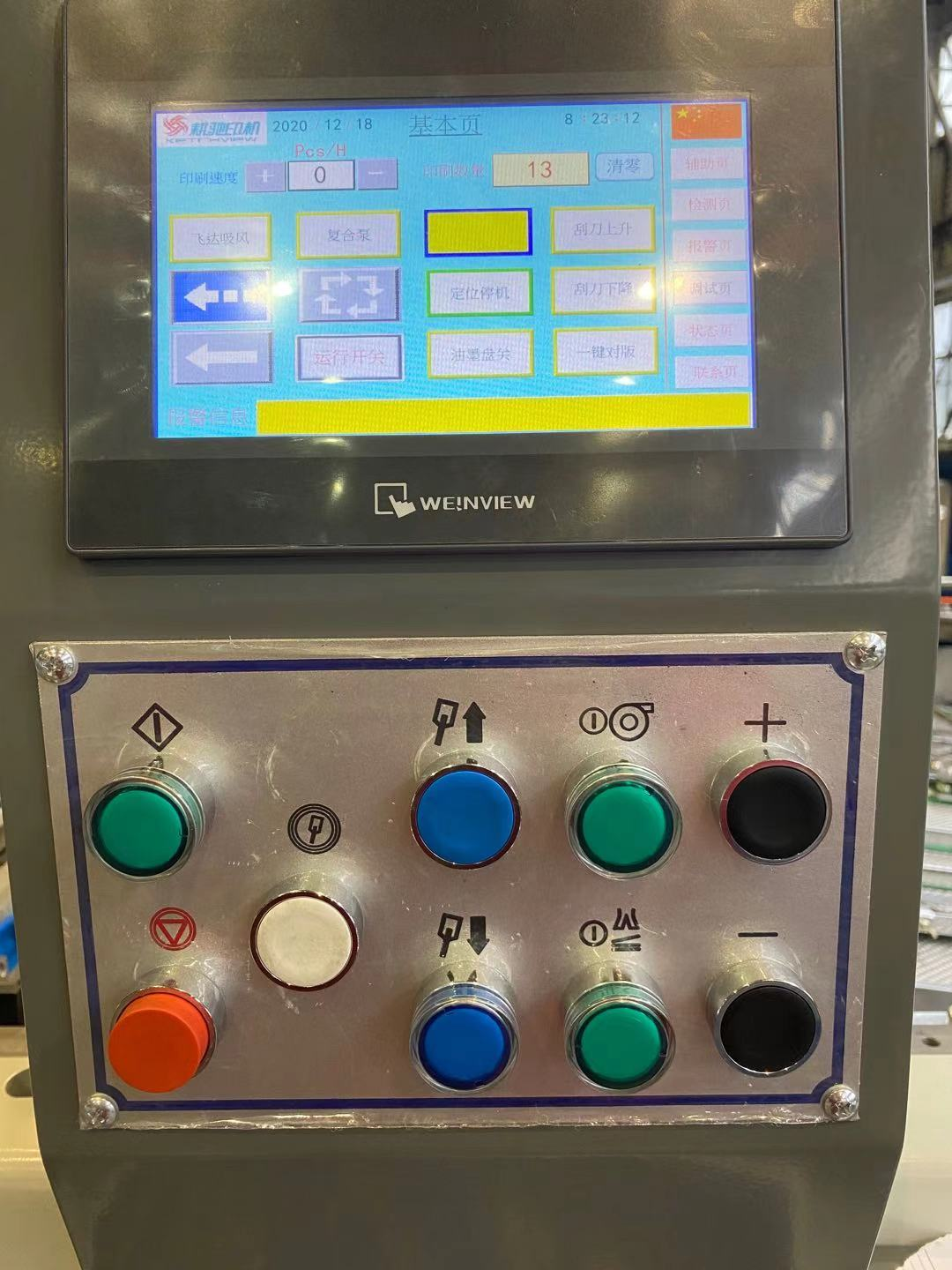

5. Mitsubishi PLC, Yaskawa Frequency components, to ensure the system reliability and stability, the redesigned operation panel operation is more convenient and humanized

6.The operating system is equipped with a 7-inch touch screen, and the redesigned interface makes it more convenient and faster, and the operation is more intuitive.

7. The complete set of AirTAC pneumatic system reliable pressure holding performance and long service life.

Technical parameters:

Model | GST1050 |

Max paper size | 1050 X 750mm |

Min paper size | 560 X 350mm |

Max printing area | 1050 X 740mm |

Screen Frame Size | 1300 X 1170mm |

Paper thickness | 90-450g/m2 |

Printing speed | 500-4000pcs/h |

Total power | 3P 380v 50hz 11kw |

Total weight | 5500kgs |

Dimension | 3800 X 3200X1500mm |

2. GUV1050 UV Drying Machine

The dryer is widely used for drying UV ink printed on paper, PCB. PEC and nameplate of instrument printing etc.

It uses special wave length to solidify the UV ink. Through this reacting, it can give the printing surface high hardness, brightness, anti-attrition and anti-solvent

Main features:

1. The convey or belt is made of Polytetrafluoroethylene; it can endure high temperature, attrition and radiation.

The stepless speed-adjusting device makes driving more steadily. It can be available to many printing modes

2. whatever handwork, semi-automatic and, high-speed automatic printing.

3. Through two sets of air-blower system, the paper can adhere to the belt firmly.

4. The machine can work in many modes: single-lamp, multi-lamps or half-power solidifying etc, which can save electric power and extend the lamp’s life.

5. The machine has stretching device and automatic rectifying device.

6. There are 4 foot-wheels fixed under the machine which can move the machine easily.

7. Electronic-transformer with stepless power-adjustment

8. UV lamp exhaust, conveyor belt under air suction, conveyor light box exhaust

9. The height of the lamp is adjustable, and the wire grid is pulled down to prevent the burning of jammed paper

10. Equipped with light box opening alarm, paper jam alarm, light box high temperature protection and other safety protection;

Technical parameters:

Model | GUV1050 |

Max conveying width | 1150mm |

Conveyor Belt Speed | 0-65m/min |

UV Lamp | 10kw X 3pcs |

Wrinkle lamp | 40w X 4pcs |

Total power | 3P, 380v, 50hz 45kw |

Total weight | 1200kg |

Dimension | 4500 X 1815 X 1220mm |

3.GLT-1050 Cold foil stamping machine

The equipment is connected with semi-automatic screen printing machine/full-automatic screen printing machine to complete the cold stamping process.

Features:

The machine can be connected with semi-automatic and full-automatic screen printing machine, with snowflake wrinkle detonator, UV curing machine, automatic paper delivery machine to become a collection of wrinkle ink technology, Snowflake Ink Technology, UV glazing, cold ironing and other multi-purpose production line.

Main advantages of the equipment:

1. Paper Bridge: negative pressure transfer platform, adjustable height up and down, a variety of height can match the front-end equipment.

2. The former device: through the photoelectric and touch screen settings, the tilt of the material can be corrected to flat into the hot stamping mechanism.

3. High-temperature silicon roller: the oil temperature heating method, low uniform deformation of roller temperature, longer service life.

4. Pre-heating rotating mechanism: pre-heating bronzing roller automatic rotation so that the drum temperature in the heating phase more uniform and fast.

5. Intelligent man-machine interactive interface: it adopts industrial control touch screen, the operation and setting are simple and clear.

6. Remote upgrade and trouble shooting: Siemens PLC is used for centralized control, with faster and more stable response. With Network C debugging module, can judge the problem and modify the program remotely.

7. Pressure booster system: equipment pressure booster cylinder, pressure more stable.

8. Gold Jump Settings: through photoelectric and PLC system settings, paper and paper to complete the jump between the jump and the paper within the jump of the gold position.

9. Solid material: high-rigid Precision Panel: using 25mm steel plate processing, equipment running more stable.

10. Stamping paper with: equipment compatible with 1-inch core, 3-inch core stamping film (available special cold stamping paper and some hot stamping paper) .

11. The use of safety Chuck: Bronzing paper simple installation, air shaft running safety.

12. luxurious configuration: the whole machine pneumatic components, are used in Taiwan Yadek, encoder using German Sike, heat-resistant bearings are

Technical parameters of equipment:

Parameter items | GLT1050 |

Maximum working width | 1100mm |

Minimum working size | 350mm |

Maximum stamping area | 1050mm |

Weight of paper | 157g -450 g |

Maximum diameter of film material | Φ200 |

Maximum diameter of film material | 1050mm |

Maximum delivery speed | 4000 pcs/h (cold foil stamping working speed 500-2000pcs/h) |

Total power of the equipment | 8.5kw |

Total weight of equipment | ≈700kg |

Size of equipment (length × width × height) | 2000×2100×1460mm |

4.GSZ-1050 Full Automatic Stacker

GSZ sheet stacker is one of accessorial equipment to automatic cylinder screen printing machine, It is used to collect and pile paper which can improve you product efficiency

Features

1. The conveyor belt speed is infinitely adjusted by the frequency converter

2. The paper falling table automatically descends according to the material stacking, and can land directly to the ground, which is convenient for the forklift to load and unload the material

3. The whole paper mechanism adopts double-shaft cylinder to work, which is stable and reliable

4. The electrical control system of the whole machine adopts Chint and Delta control

5. With counting function, can record the receiving number

Main technical parameters:

Model | GSZ-1050 |

Max.Paper size | 1050×750 mm |

Min.Paper size | 400×350 mm |

Top speed | 4000 sheet/h |

Power | 3P 380V 50Hz 1.5KW (5A) |

Total weight | 650kg |

Overall size | 1900×1700×1200 mm |

GST1050 Automatic screen printing spot UV & cold foil stamping line

GST-1050 Full Automatic Stop Cylinder Screen Press adopts the classical stop cylinder technology with the advantages such as: paper located exactly and steadily, high precision, high speed, low noise, high degree automatization and so on, it is suitable for printing on ceramic and glass applique, electron industry (film switch, flexible circuitry, meter panel, mobile telephone), advertisement, packing and printing, brand, textile transfer, special technics etc.

Main features:

1. Driven by a special brake motor for frequency conversion, the whole machine is centrally controlled and operated by Mitsubishi PLC programmable controller, 7-inch color touch screen operation interface, displaying all functional data, printing operation is simpler and more convenient;

2. Automatic optical fiber positioning detection throughout the process, line failure, paperless, jammed scraper automatically rise and stop or not, reduce the waste of printing paper;

3. Set up a perfect alarm bell alarm system to prompt the operator to carry out targeted troubleshooting, so that maintenance is easy and fast;

4. The whole set of electrical components are imported products from Schneider and Yaskawa, which greatly improves the stability of the electrical system and reduces the frequency and difficulty of maintenance and overhaul;

5. The cast iron frame and some components precision processed by the CNC "machining center" ensure the accuracy of key parts and ensure the stable and long-term rapid operation of the machine;

6. The printing cylinder is made of stainless steel 316L material, which is precise and durable; The flexible range of the paper tooth is designed to be flexible, which is convenient to adjust at any time when printing on different thicknesses and thin papers;

7. The paper output table that can be flipped 90 degrees, double conveying adjustable speed belt, practical size paper, convenient for screen cleaning, loading and unloading; Screen plate fine-tuning device, which can be adjusted in all directions up and down, front and back, left and right;

8. Good gray cast iron (HT250), wall plate and base cast by aluminum mold, after aging treatment, and then processed by imported large-scale three-dimensional machining center, high precision level requirements, smaller processing error, the operation of the whole machine is more stable and reliable.

9. Centralized lubrication control system: automatic lubrication of main transmission components, effectively prolonging the use accuracy and machine life;

10. The appearance is made of environmentally friendly primer, which is carefully polished and painted, and finally the outer surface cover varnish;

11. All pneumatic components adopt Taiwan Airtac brand, and the air pump adopts Becker vacuum pump;

12. Printing knife and feeder platform are precisely controlled by separate brakes, and the pressure is uniform;

13. The machine automatically detects whether there is paper or not, and automatically increases and lowers the speed;

14. One-button pneumatic switching device for pulling&pushing side lay

15. Mesh frame drawer design, can be pulled out as a whole, which is convenient for cleaning and loading and unloading of screen plates, and convenient for the calibration and adjustment of screen plates and prints.

Remark:

Equipped with independent single sheet paper reduction mechanism, feeding is more stable and reliable

Front gauge, pull gauge Japanese Keyence fiber inspection;

The paper conveying table photoelectric detection of whether there is material, deceleration and shutdown;

The latest double sheet detector

Details:

1. Feeder

The original rear pick-up feeder technology taken from the offset Press, ensures stable and smooth feeding of various types of substrate. Dependant on the substrate, overlapped or single sheet feed can be selected easily. Four suck and four delivery feeding system.

2. Delivery board

Imported stain steel delivery board, less static and friction. Rubber and the nylon wheel are suitable for the thin and thick paper adjustment

3. New designed pull and push lay

Controlled by the pneumatic switch, easy to switch the thin paper and thick paper, specially suitable for E-corrugated board printing

4. Paper output table

Double vacuum conveyor belt, controlled by the independent frequency. Suitable for different sheet size, avoid the damage to sheets and prevent the paper stuck,

The paper output table that can be flipped 90 degrees, convenient for screen cleaning, loading and unloading

5. Mitsubishi PLC, Yaskawa Frequency components, to ensure the system reliability and stability, the redesigned operation panel operation is more convenient and humanized

6.The operating system is equipped with a 7-inch touch screen, and the redesigned interface makes it more convenient and faster, and the operation is more intuitive.

7. The complete set of AirTAC pneumatic system reliable pressure holding performance and long service life.

Technical parameters:

Model | GST1050 |

Max paper size | 1050 X 750mm |

Min paper size | 560 X 350mm |

Max printing area | 1050 X 740mm |

Screen Frame Size | 1300 X 1170mm |

Paper thickness | 90-450g/m2 |

Printing speed | 500-4000pcs/h |

Total power | 3P 380v 50hz 11kw |

Total weight | 5500kgs |

Dimension | 3800 X 3200X1500mm |

2. GUV1050 UV Drying Machine

The dryer is widely used for drying UV ink printed on paper, PCB. PEC and nameplate of instrument printing etc.

It uses special wave length to solidify the UV ink. Through this reacting, it can give the printing surface high hardness, brightness, anti-attrition and anti-solvent

Main features:

1. The convey or belt is made of Polytetrafluoroethylene; it can endure high temperature, attrition and radiation.

The stepless speed-adjusting device makes driving more steadily. It can be available to many printing modes

2. whatever handwork, semi-automatic and, high-speed automatic printing.

3. Through two sets of air-blower system, the paper can adhere to the belt firmly.

4. The machine can work in many modes: single-lamp, multi-lamps or half-power solidifying etc, which can save electric power and extend the lamp’s life.

5. The machine has stretching device and automatic rectifying device.

6. There are 4 foot-wheels fixed under the machine which can move the machine easily.

7. Electronic-transformer with stepless power-adjustment

8. UV lamp exhaust, conveyor belt under air suction, conveyor light box exhaust

9. The height of the lamp is adjustable, and the wire grid is pulled down to prevent the burning of jammed paper

10. Equipped with light box opening alarm, paper jam alarm, light box high temperature protection and other safety protection;

Technical parameters:

Model | GUV1050 |

Max conveying width | 1150mm |

Conveyor Belt Speed | 0-65m/min |

UV Lamp | 10kw X 3pcs |

Wrinkle lamp | 40w X 4pcs |

Total power | 3P, 380v, 50hz 45kw |

Total weight | 1200kg |

Dimension | 4500 X 1815 X 1220mm |

3.GLT-1050 Cold foil stamping machine

The equipment is connected with semi-automatic screen printing machine/full-automatic screen printing machine to complete the cold stamping process.

Features:

The machine can be connected with semi-automatic and full-automatic screen printing machine, with snowflake wrinkle detonator, UV curing machine, automatic paper delivery machine to become a collection of wrinkle ink technology, Snowflake Ink Technology, UV glazing, cold ironing and other multi-purpose production line.

Main advantages of the equipment:

1. Paper Bridge: negative pressure transfer platform, adjustable height up and down, a variety of height can match the front-end equipment.

2. The former device: through the photoelectric and touch screen settings, the tilt of the material can be corrected to flat into the hot stamping mechanism.

3. High-temperature silicon roller: the oil temperature heating method, low uniform deformation of roller temperature, longer service life.

4. Pre-heating rotating mechanism: pre-heating bronzing roller automatic rotation so that the drum temperature in the heating phase more uniform and fast.

5. Intelligent man-machine interactive interface: it adopts industrial control touch screen, the operation and setting are simple and clear.

6. Remote upgrade and trouble shooting: Siemens PLC is used for centralized control, with faster and more stable response. With Network C debugging module, can judge the problem and modify the program remotely.

7. Pressure booster system: equipment pressure booster cylinder, pressure more stable.

8. Gold Jump Settings: through photoelectric and PLC system settings, paper and paper to complete the jump between the jump and the paper within the jump of the gold position.

9. Solid material: high-rigid Precision Panel: using 25mm steel plate processing, equipment running more stable.

10. Stamping paper with: equipment compatible with 1-inch core, 3-inch core stamping film (available special cold stamping paper and some hot stamping paper) .

11. The use of safety Chuck: Bronzing paper simple installation, air shaft running safety.

12. luxurious configuration: the whole machine pneumatic components, are used in Taiwan Yadek, encoder using German Sike, heat-resistant bearings are

Technical parameters of equipment:

Parameter items | GLT1050 |

Maximum working width | 1100mm |

Minimum working size | 350mm |

Maximum stamping area | 1050mm |

Weight of paper | 157g -450 g |

Maximum diameter of film material | Φ200 |

Maximum diameter of film material | 1050mm |

Maximum delivery speed | 4000 pcs/h (cold foil stamping working speed 500-2000pcs/h) |

Total power of the equipment | 8.5kw |

Total weight of equipment | ≈700kg |

Size of equipment (length × width × height) | 2000×2100×1460mm |

4.GSZ-1050 Full Automatic Stacker

GSZ sheet stacker is one of accessorial equipment to automatic cylinder screen printing machine, It is used to collect and pile paper which can improve you product efficiency

Features

1. The conveyor belt speed is infinitely adjusted by the frequency converter

2. The paper falling table automatically descends according to the material stacking, and can land directly to the ground, which is convenient for the forklift to load and unload the material

3. The whole paper mechanism adopts double-shaft cylinder to work, which is stable and reliable

4. The electrical control system of the whole machine adopts Chint and Delta control

5. With counting function, can record the receiving number

Main technical parameters:

Model | GSZ-1050 |

Max.Paper size | 1050×750 mm |

Min.Paper size | 400×350 mm |

Top speed | 4000 sheet/h |

Power | 3P 380V 50Hz 1.5KW (5A) |

Total weight | 650kg |

Overall size | 1900×1700×1200 mm |

Home | About Us | Products | Cases | Video | News | Contact Us | Privacy Policy