- All

- Product Name

- Product Keyword

- Product Model

- Product Summary

- Product Description

- Multi Field Search

| Availability: | |

|---|---|

| Quantity: | |

Automatic screen printing cold foil stamping /UV coating producing line

Producing line photo

Floor Plan

GST1050 Automatic stop cylinder screen printing machine

Main features:

1. Driven by a special brake motor for frequency conversion, the whole machine is centrally controlled and operated by Mitsubishi PLC programmable controller, 7-inch color touch screen operation interface, displaying all functional data, printing operation is simpler and more convenient;

2. Automatic optical fiber positioning detection throughout the process, line failure, paperless, jammed scraper automatically rise and stop or not, reduce the waste of printing paper;

3. Set up a perfect alarm bell alarm system to prompt the operator to carry out targeted troubleshooting, so that maintenance is easy and fast;

4. The whole set of electrical components are imported products from Schneider and Yaskawa, which greatly improves the stability of the electrical system and reduces the frequency and difficulty of maintenance and overhaul;

5. The cast iron frame and some components precision processed by the CNC "machining center" ensure the accuracy of key parts and ensure the stable and long-term rapid operation of the machine;

6. The printing cylinder is made of stainless steel 316L material, which is precise and durable; The flexible range of the paper tooth is designed to be flexible, which is convenient to adjust at any time when printing on different thicknesses and thin papers;

7. The paper output table that can be flipped 90 degrees, double conveying adjustable speed belt, practical size paper, convenient for screen cleaning, loading and unloading; Screen plate fine-tuning device, which can be adjusted in all directions up and down, front and back, left and right;

8. Good gray cast iron (HT250), wall plate and base cast by aluminum mold, after aging treatment, and then processed by imported large-scale three-dimensional machining center, high precision level requirements, smaller processing error, the operation of the whole machine is more stable and reliable.

9. Centralized lubrication control system: automatic lubrication of main transmission components, effectively prolonging the use accuracy and machine life;

10. The appearance is made of environmentally friendly primer, which is carefully polished and painted, and finally the outer surface cover varnish;

11. All pneumatic components adopt Taiwan Airtac brand, and the air pump adopts Becker vacuum pump;

12. Printing knife and feeder platform are precisely controlled by separate brakes, and the pressure is uniform;

13. The machine automatically detects whether there is paper or not, and automatically increases and lowers the speed;

14. One-button pneumatic switching device for pulling&pushing side lay

15. Mesh frame drawer design, can be pulled out as a whole, which is convenient for cleaning and loading and unloading of screen plates, and convenient for the calibration and adjustment of screen plates and prints.

Main technical parameter

Model | GST-1050 | GST-1020(optional) | GSP-1020(optional) |

Max. paper size | 1050 X 750MM | 1020 X 720MM | 1020X740mm |

Min. paper size | 500 X 350MM | 560 X 350MM | 500x350mm |

Max. Printing size | 1050 X 740MM | 1020 X 710MM | 1020X720mm |

Paper thickness*1 | 90-420GSM | 100-350GSM | 120-350 g/m2 |

Registration accuracy | ≤0.10MM | ≤0.10MM | ≤0.1MM |

Frame size | 1300 x 1170MM | 1280 x 1140MM | 1280X1140mm |

Margin | ≤12MM | ≤12MM | ≤12MM |

Printing speed*2 | 600-4000PCS/H | 500-3500PCS/H | 1000-3000 p/h |

Power | 3P 380V 50HZ 11.0KW | 3P 380V 50HZ 11.0KW | 1280X1140mm |

Weight | 5500KGS | 5200KGS | 5000KGS |

Overall size | 3750X3100X1750MM | 3900X2900X1800MM | 3600x2350x1300mm |

*1 Depends on the material hardness

*2 Depends on the kind of printing substrate and printing conditions, figures may be changed

Remark:

Equipped with independent single sheet paper reduction mechanism, feeding is more stable and reliable

Front gauge, pull gauge Japanese Keyence fiber inspection;

The paper conveying table photoelectric detection of whether there is material, deceleration and shutdown;

The latest double sheet detector

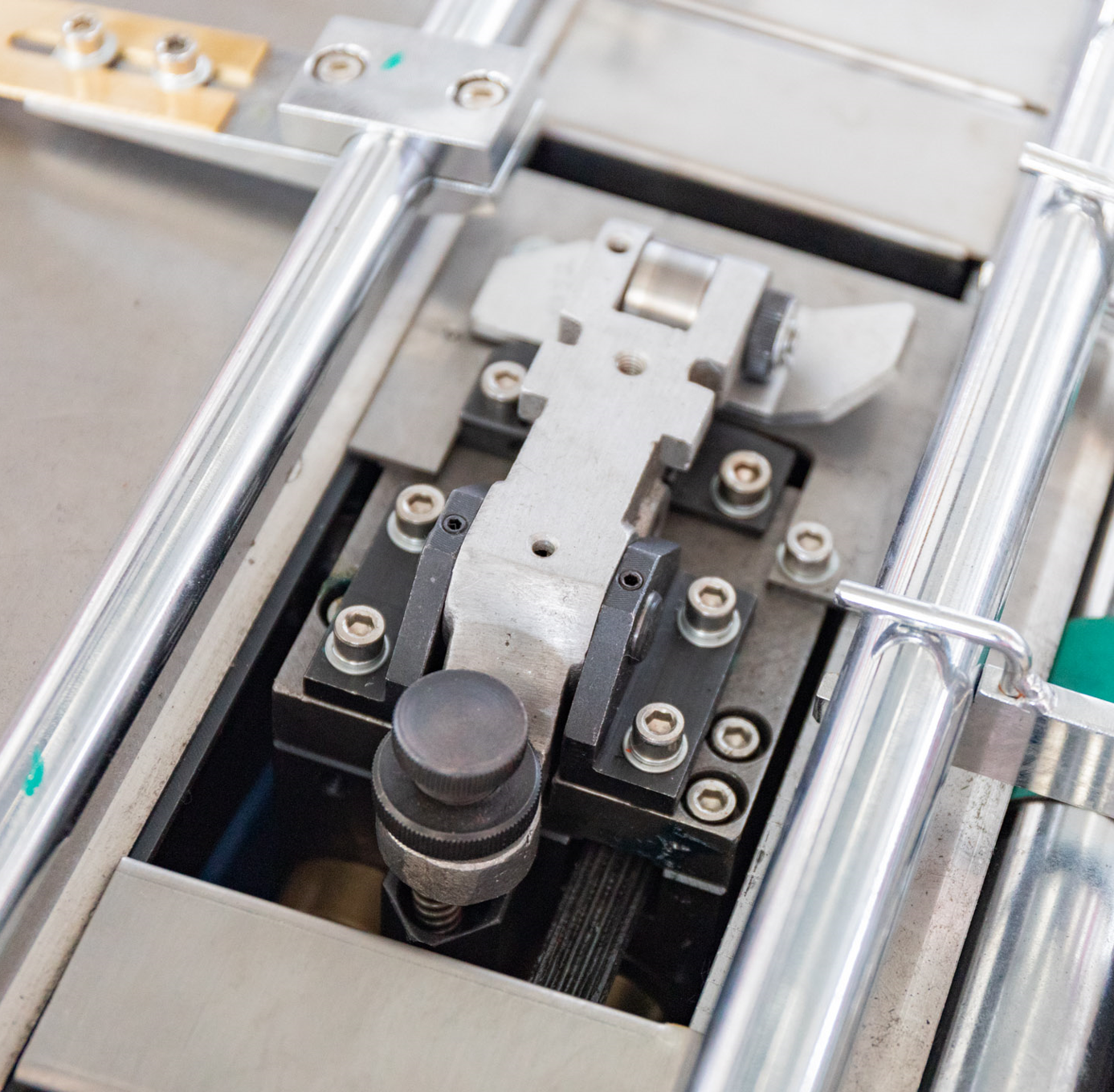

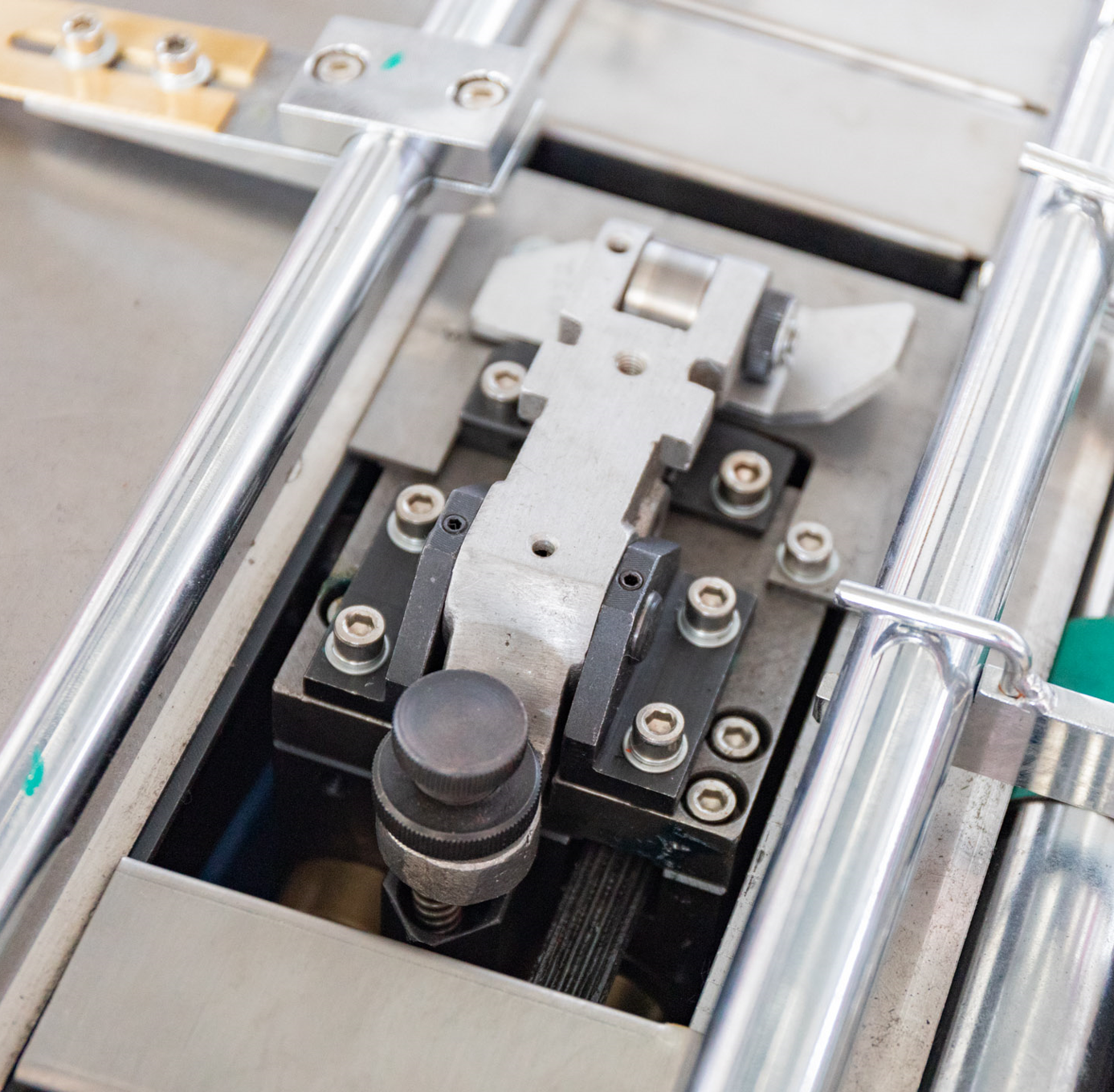

Details

1. Feeder

The original rear pick-up feeder technology taken from the offset Press, ensures stable and smooth feeding of various types of substrate. Dependant on the substrate, overlapped or single sheet feed can be selected easily. Four suck and four delivery feeding system.

2. Delivery board

Imported stain steel delivery board, less static and friction. Rubber and the nylon wheel are suitable for the thin and thick paper adjustment

3. New designed pull and push lay

Controlled by the pneumatic switch, easy to switch the thin paper and thick paper, specially suitable for E-corrugated board printing

4. Paper output table

Double vacuum conveyor belt, controlled by the independent frequency. Suitable for different sheet size, avoid the damage to sheets and prevent the paper stuck,

The paper output table that can be flipped 90 degrees, convenient for screen cleaning, loading and unloading

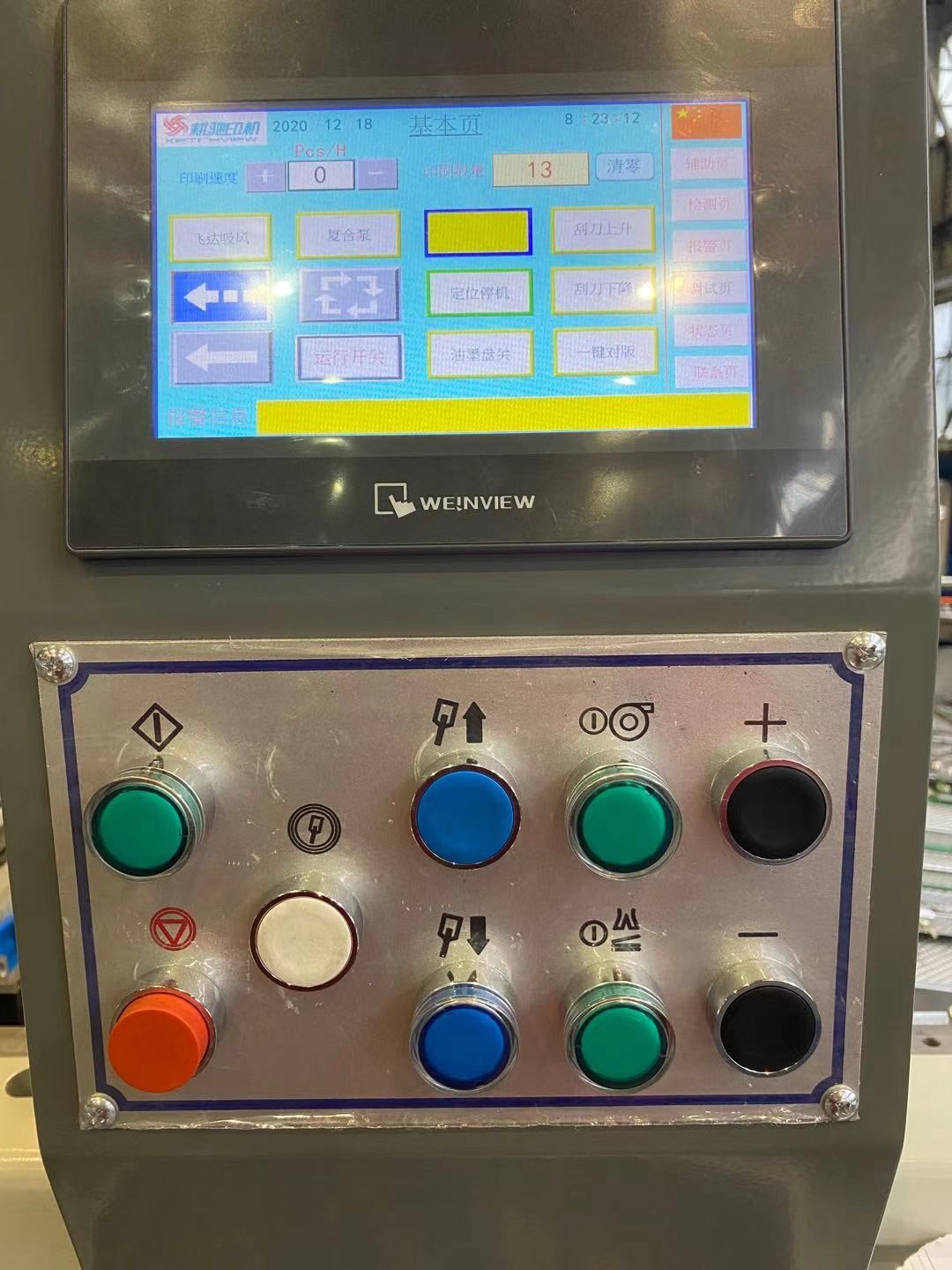

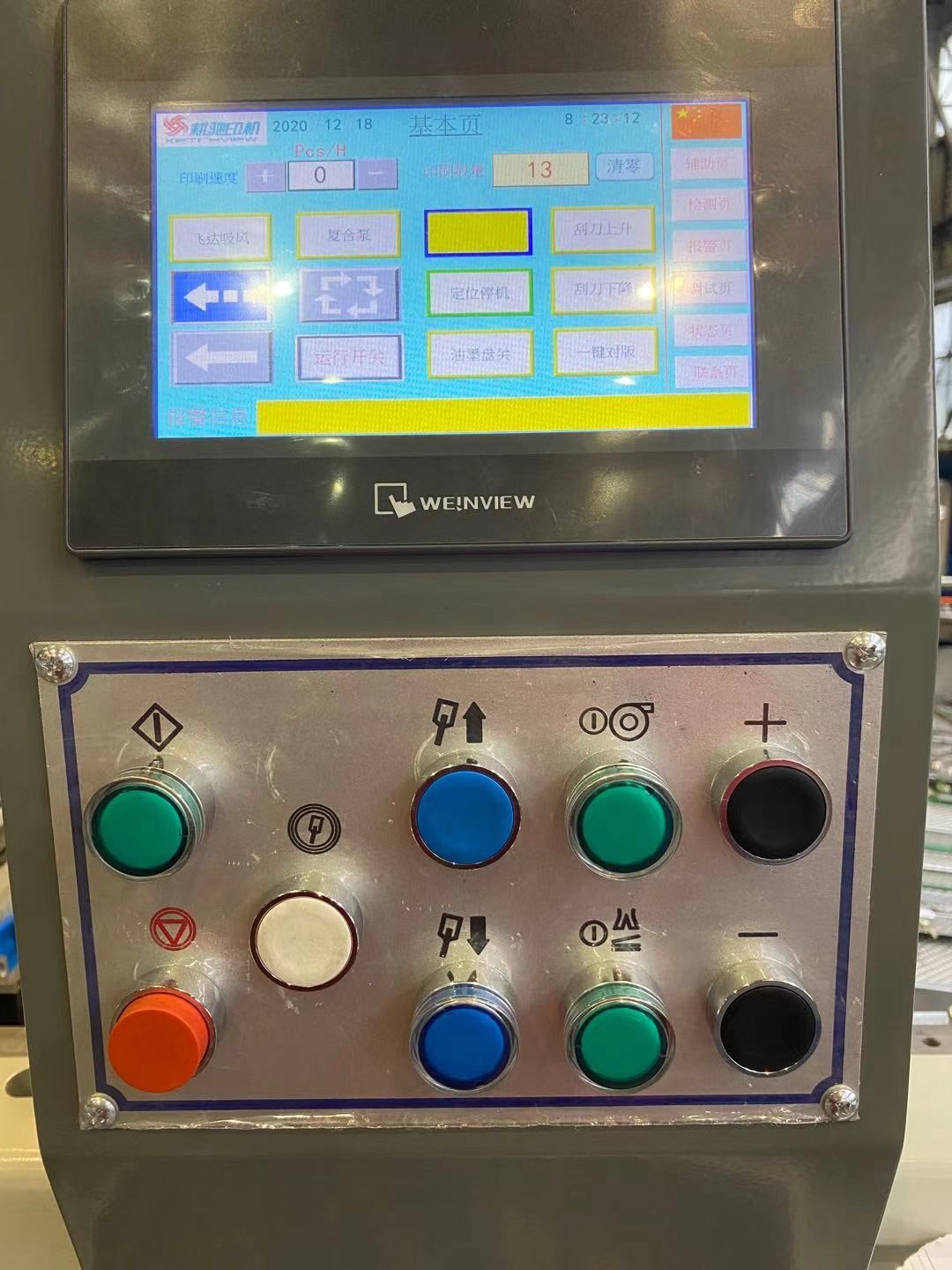

5. Mitsubishi PLC, Yaskawa Frequency components, to ensure the system reliability and stability, the redesigned operation panel operation is more convenient and humanized

6.The operating system is equipped with a 7-inch touch screen, and the redesigned interface makes it more convenient and faster, and the operation is more intuitive.

7. The complete set of AirTAC pneumatic system reliable pressure holding performance and long service life.

Configuration list of GST-1050

No. | Name | Brand | Type specification | Quantity |

1 | Thermal relay | Weidmuller | ZB12C-1.6 | 1 |

2 | Thermal relay | Weidmuller | ZB12C-4 | 3 |

3 | Button | TAYEE | ||

4 | Inverter | Yaskawa | HB4A0018 | 1 |

5 | Circuit breaker | EATON | PKZMC-32 | 1 |

6 | Optical fiber | OMRON | E32-CC200 | 2 |

7 | Amplifier | OMRON | E3X-NA11 | 2 |

8 | Optical fibre amplifier | KEYENCE | FU-6F FS-N18N | 7 |

9 | Limit switch | OMRON | AZ7311 | 5 |

10 | Switching power | MEAN WELL | DR-75-24 | 1 |

11 | Limit switch | OMRON | 1 | |

12 | Vacuum pump | BECKER | KVT60 | 1 |

13 | Encoder | HEDSS | SC-3806-401G720 | 1 |

14 | Touch screen | WEINVIEW | SA12.1 | 1 |

15 | Proximity switch | OMRON | EZS-W23,EZS-W24 | 2 |

16 | Terminal block | Weidmuller | N |

UVY-106CS Cold foil Stamping machine

Description | Model | Function |

Cold foil Stamping &Hologram images transferring machine | UVY-106CS | Cold foil Stamping Spot UV varnish |

UVY-106CS transfer machine is our company's self-developed high-tech products, the unit can be used with printing machine, UV coating machine, screen printing machine and other equipments to achieve the cold foil stamping process, which saves the cost and space

The equipment has won a number of technical awards, suitable for cigarette boxes, wine boxes, cosmetics boxes, gift boxes and other high-grade printing

Technological process

Features

Material saving

It has good protective effect on the printed products which can avoid glazing process, the laser film can be recycled without any treatment.Comparing with the composite process, it can save money.

Environmental protection

The process adopts a post-processing method of embossing on semi-finished printed products, only leaving laser text and patterns on the product which is conducive to the recycling or natural degradation of wasting printed products.

UVY-106CS photo for reference

Model | UVY-106CS |

Max.Working Breadth | 740×1040mm |

Min.Working Breadth | 393×546mm |

Max.Printing Area | 730×1030mm |

Sheet Weight | 90-450 g/㎡ |

Max.Diameter of Film | Ф500mm |

Max.Width of Film | 1060mm |

Max.Mechanical Speed | Cold foil Stamping: 2000 sheet/h |

Min Divided Roll Width | 80mm |

Max Divided Rolls | 8 rollers |

UV Lamp | 8KW×4pcs |

IR Lamp | 3KW×4pcs |

Outer Dimensions | 6.2×4.1×3.8M |

Total Weight | ≈5.6T |

Total Power | ≈85.8kw |

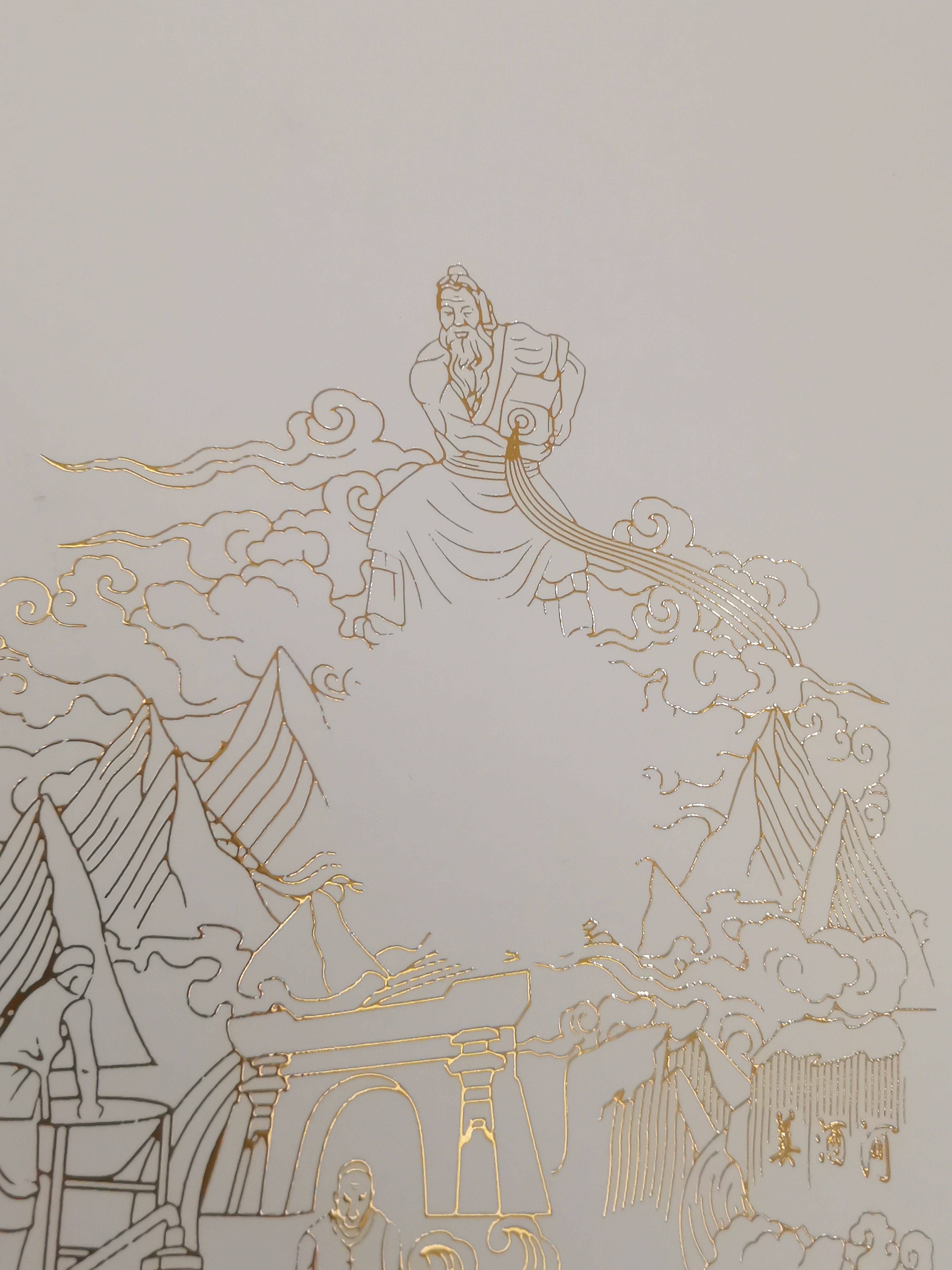

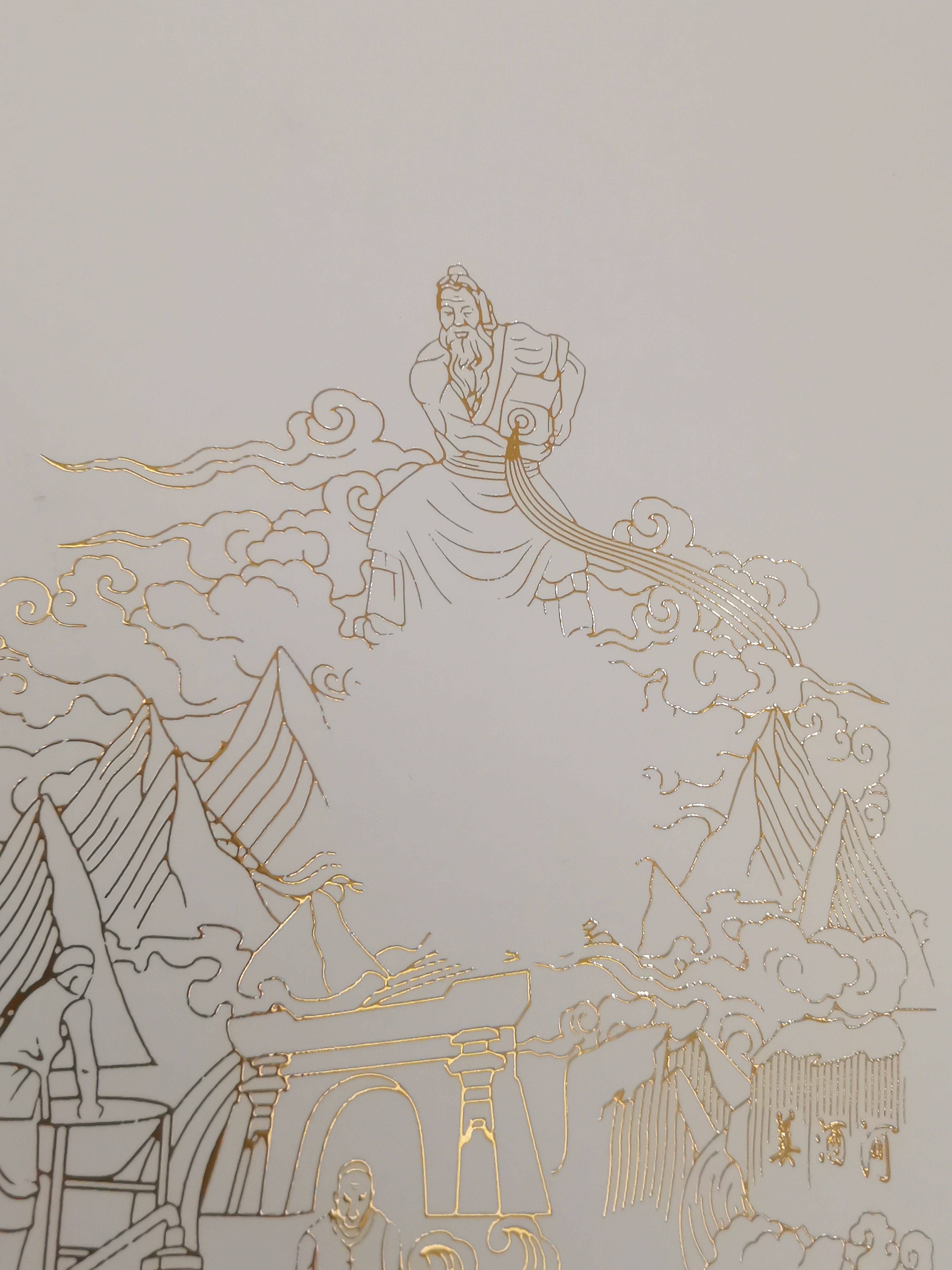

Samples

Cold foil Stamping

Automatic screen printing cold foil stamping /UV coating producing line

Producing line photo

Floor Plan

GST1050 Automatic stop cylinder screen printing machine

Main features:

1. Driven by a special brake motor for frequency conversion, the whole machine is centrally controlled and operated by Mitsubishi PLC programmable controller, 7-inch color touch screen operation interface, displaying all functional data, printing operation is simpler and more convenient;

2. Automatic optical fiber positioning detection throughout the process, line failure, paperless, jammed scraper automatically rise and stop or not, reduce the waste of printing paper;

3. Set up a perfect alarm bell alarm system to prompt the operator to carry out targeted troubleshooting, so that maintenance is easy and fast;

4. The whole set of electrical components are imported products from Schneider and Yaskawa, which greatly improves the stability of the electrical system and reduces the frequency and difficulty of maintenance and overhaul;

5. The cast iron frame and some components precision processed by the CNC "machining center" ensure the accuracy of key parts and ensure the stable and long-term rapid operation of the machine;

6. The printing cylinder is made of stainless steel 316L material, which is precise and durable; The flexible range of the paper tooth is designed to be flexible, which is convenient to adjust at any time when printing on different thicknesses and thin papers;

7. The paper output table that can be flipped 90 degrees, double conveying adjustable speed belt, practical size paper, convenient for screen cleaning, loading and unloading; Screen plate fine-tuning device, which can be adjusted in all directions up and down, front and back, left and right;

8. Good gray cast iron (HT250), wall plate and base cast by aluminum mold, after aging treatment, and then processed by imported large-scale three-dimensional machining center, high precision level requirements, smaller processing error, the operation of the whole machine is more stable and reliable.

9. Centralized lubrication control system: automatic lubrication of main transmission components, effectively prolonging the use accuracy and machine life;

10. The appearance is made of environmentally friendly primer, which is carefully polished and painted, and finally the outer surface cover varnish;

11. All pneumatic components adopt Taiwan Airtac brand, and the air pump adopts Becker vacuum pump;

12. Printing knife and feeder platform are precisely controlled by separate brakes, and the pressure is uniform;

13. The machine automatically detects whether there is paper or not, and automatically increases and lowers the speed;

14. One-button pneumatic switching device for pulling&pushing side lay

15. Mesh frame drawer design, can be pulled out as a whole, which is convenient for cleaning and loading and unloading of screen plates, and convenient for the calibration and adjustment of screen plates and prints.

Main technical parameter

Model | GST-1050 | GST-1020(optional) | GSP-1020(optional) |

Max. paper size | 1050 X 750MM | 1020 X 720MM | 1020X740mm |

Min. paper size | 500 X 350MM | 560 X 350MM | 500x350mm |

Max. Printing size | 1050 X 740MM | 1020 X 710MM | 1020X720mm |

Paper thickness*1 | 90-420GSM | 100-350GSM | 120-350 g/m2 |

Registration accuracy | ≤0.10MM | ≤0.10MM | ≤0.1MM |

Frame size | 1300 x 1170MM | 1280 x 1140MM | 1280X1140mm |

Margin | ≤12MM | ≤12MM | ≤12MM |

Printing speed*2 | 600-4000PCS/H | 500-3500PCS/H | 1000-3000 p/h |

Power | 3P 380V 50HZ 11.0KW | 3P 380V 50HZ 11.0KW | 1280X1140mm |

Weight | 5500KGS | 5200KGS | 5000KGS |

Overall size | 3750X3100X1750MM | 3900X2900X1800MM | 3600x2350x1300mm |

*1 Depends on the material hardness

*2 Depends on the kind of printing substrate and printing conditions, figures may be changed

Remark:

Equipped with independent single sheet paper reduction mechanism, feeding is more stable and reliable

Front gauge, pull gauge Japanese Keyence fiber inspection;

The paper conveying table photoelectric detection of whether there is material, deceleration and shutdown;

The latest double sheet detector

Details

1. Feeder

The original rear pick-up feeder technology taken from the offset Press, ensures stable and smooth feeding of various types of substrate. Dependant on the substrate, overlapped or single sheet feed can be selected easily. Four suck and four delivery feeding system.

2. Delivery board

Imported stain steel delivery board, less static and friction. Rubber and the nylon wheel are suitable for the thin and thick paper adjustment

3. New designed pull and push lay

Controlled by the pneumatic switch, easy to switch the thin paper and thick paper, specially suitable for E-corrugated board printing

4. Paper output table

Double vacuum conveyor belt, controlled by the independent frequency. Suitable for different sheet size, avoid the damage to sheets and prevent the paper stuck,

The paper output table that can be flipped 90 degrees, convenient for screen cleaning, loading and unloading

5. Mitsubishi PLC, Yaskawa Frequency components, to ensure the system reliability and stability, the redesigned operation panel operation is more convenient and humanized

6.The operating system is equipped with a 7-inch touch screen, and the redesigned interface makes it more convenient and faster, and the operation is more intuitive.

7. The complete set of AirTAC pneumatic system reliable pressure holding performance and long service life.

Configuration list of GST-1050

No. | Name | Brand | Type specification | Quantity |

1 | Thermal relay | Weidmuller | ZB12C-1.6 | 1 |

2 | Thermal relay | Weidmuller | ZB12C-4 | 3 |

3 | Button | TAYEE | ||

4 | Inverter | Yaskawa | HB4A0018 | 1 |

5 | Circuit breaker | EATON | PKZMC-32 | 1 |

6 | Optical fiber | OMRON | E32-CC200 | 2 |

7 | Amplifier | OMRON | E3X-NA11 | 2 |

8 | Optical fibre amplifier | KEYENCE | FU-6F FS-N18N | 7 |

9 | Limit switch | OMRON | AZ7311 | 5 |

10 | Switching power | MEAN WELL | DR-75-24 | 1 |

11 | Limit switch | OMRON | 1 | |

12 | Vacuum pump | BECKER | KVT60 | 1 |

13 | Encoder | HEDSS | SC-3806-401G720 | 1 |

14 | Touch screen | WEINVIEW | SA12.1 | 1 |

15 | Proximity switch | OMRON | EZS-W23,EZS-W24 | 2 |

16 | Terminal block | Weidmuller | N |

UVY-106CS Cold foil Stamping machine

Description | Model | Function |

Cold foil Stamping &Hologram images transferring machine | UVY-106CS | Cold foil Stamping Spot UV varnish |

UVY-106CS transfer machine is our company's self-developed high-tech products, the unit can be used with printing machine, UV coating machine, screen printing machine and other equipments to achieve the cold foil stamping process, which saves the cost and space

The equipment has won a number of technical awards, suitable for cigarette boxes, wine boxes, cosmetics boxes, gift boxes and other high-grade printing

Technological process

Features

Material saving

It has good protective effect on the printed products which can avoid glazing process, the laser film can be recycled without any treatment.Comparing with the composite process, it can save money.

Environmental protection

The process adopts a post-processing method of embossing on semi-finished printed products, only leaving laser text and patterns on the product which is conducive to the recycling or natural degradation of wasting printed products.

UVY-106CS photo for reference

Model | UVY-106CS |

Max.Working Breadth | 740×1040mm |

Min.Working Breadth | 393×546mm |

Max.Printing Area | 730×1030mm |

Sheet Weight | 90-450 g/㎡ |

Max.Diameter of Film | Ф500mm |

Max.Width of Film | 1060mm |

Max.Mechanical Speed | Cold foil Stamping: 2000 sheet/h |

Min Divided Roll Width | 80mm |

Max Divided Rolls | 8 rollers |

UV Lamp | 8KW×4pcs |

IR Lamp | 3KW×4pcs |

Outer Dimensions | 6.2×4.1×3.8M |

Total Weight | ≈5.6T |

Total Power | ≈85.8kw |

Samples

Cold foil Stamping

Home | About Us | Products | Cases | Video | News | Contact Us | Privacy Policy